Measure Phase

In Define

Phase where I used VSM map to show the current design and manufacture process

and a Fish Bone Diagram to highlight the areas within the process which can be

improved.

In the

measure phase I gathered data from the company’s job management software for a

number of recently completed jobs. The operator scans the bar code on the job

card which matches to process he/she is carrying out on the job. The software

gave me accurate data regarding the hours of each process used on the job.

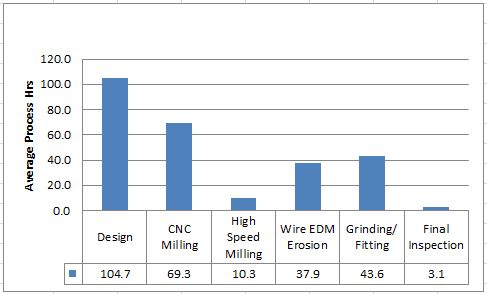

I was able to retrieve the operation hours for each job through creating a job analysis report using the job management software.

I used a column chart to plot the average hours of each operation over a number of completed jobs. The column chart showed the average hours of the operations used throughout the design and manufacture process.

I also used the job management software to retrieve the data for duration of a number of completed projects, I have plotted these on a line graph which shows the variations in lead times and the average lead-time.