Control Phase

As part of

the control phase an operational procedure was put in place to aid the design

team in designing components which suit the EDM wire erosion process where

possible. Part of the procedure was an additional design review with the production

manager in-order to appraise the designs suitability for the EDM wire erosion

process and to plan future process capacity for the wire EDM department. These

design reviews will also be used as a method of evaluating the design teams

ability to apply new design methods.

We put a

control plan in place to show the strategy that would be used to control the

improved process.

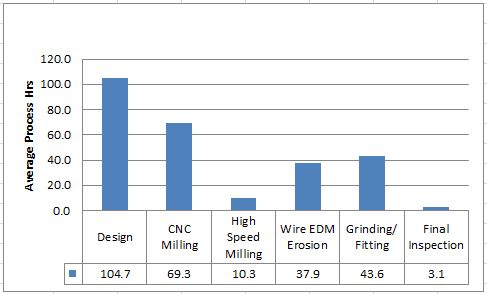

The average process hours and design and manufacture lead-time are measured using the Job management software. These metrics are taken after the completion of each job and analysed using a control chart in-order to ensure that the reductions in average process hours and design and manufacture lead-times achieved in the Improve phase is maintained in future projects.